About us Products News Contact us

Tel:86-020-37400096

Phone:136 0030 4588

13124259290(Mr. Jiang)

Fax:86-020-37403361

Mailbox:ud8888@aliyun.com

Add:Liangshi Road, Liangtian, Baiyun District, Guangzhou

COPYRIGHT @ 2020 Guangzhou Youda Coating Co., Ltd. gzud.com.cn. ALL RIGHTS RESERVED. ICP:45646546-1 Powered by www.300.cn

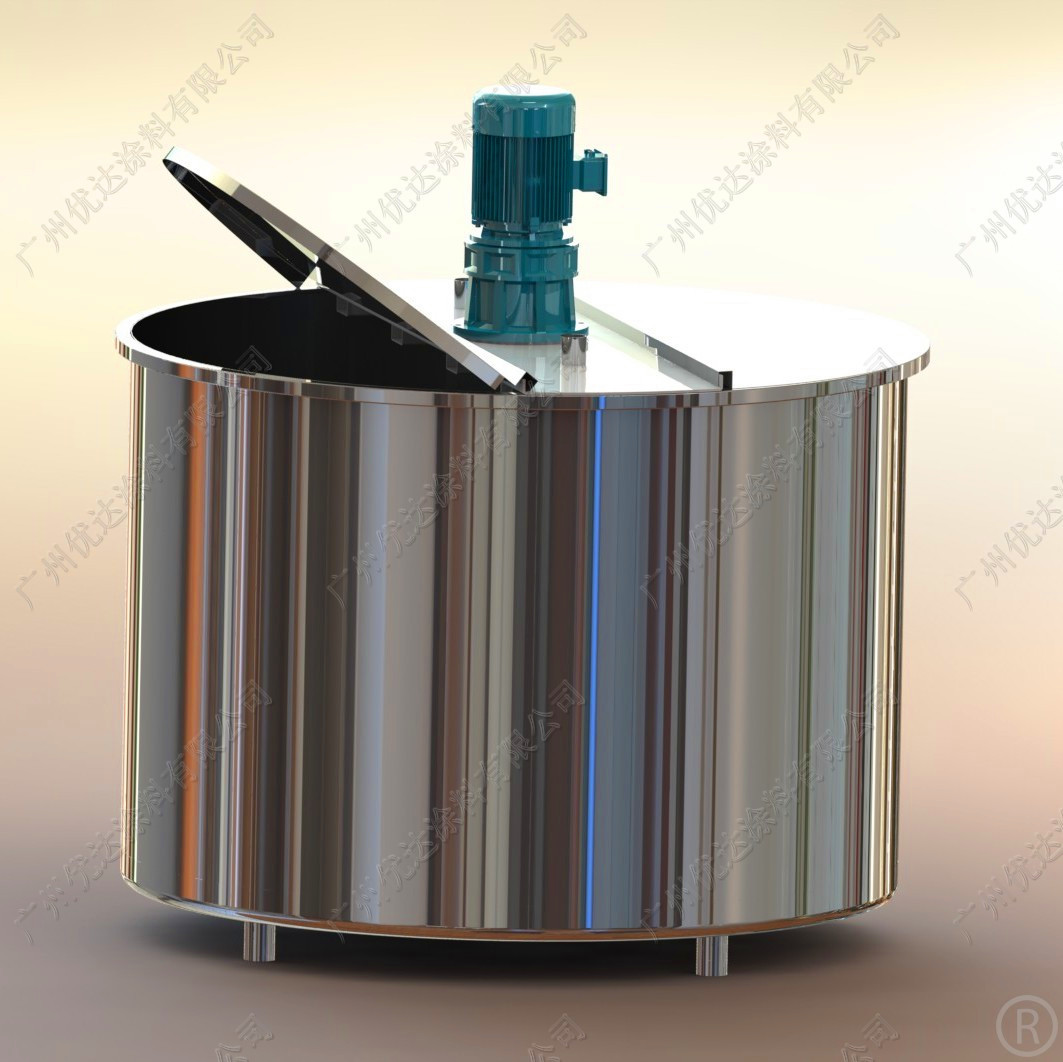

What is the effect of electrophoretic paint mixing bucket on electrophoretic paint

In the anodic electrophoretic paint industry for many years, I did not pay special attention to these details in the first few years. Looking at the mixing buckets made by the entire industry, they are almost the same, so I did not pay special attention to what is important.

High performance electrophoretic paint mixing bucket

First, in 2007, a Jiangxi customer had a nearly 55-cubic electrophoresis tank. A few days after the slot was opened, the customer's plant manager called to ask for a compensation of 1.5% of the solid fee, because the contract stated that 6% of the solid Although the slot is also slotted at 6% when it is slotted, it is invisible that about 1.5% is missing, and the compensation is inexplicable.

Field application of high performance electrophoretic paint mixing bucket

Next, in a large customer factory in northern Jiangsu in 2009, three nearly 45 cubic electrophoresis production lines were delivered to our service. When the first slot was opened, the goal was to open 6% solid content, and the result was only about 4.5%. I also feel very puzzled about this result, but I still can't think of the reason, because there is no problem with the original paint solid content, and the amount added is also correct. A few months later, when I opened the second production line, I slowed down the speed of pouring the paint into the mixing bucket and extended the mixing time after the addition to 30 minutes per barrel; so that the entire slotting time was extended to 17 hours. But after one night of testing, the solid content of the test still did not reach the expected 6%, but only slightly increased to 4.95%; but it has been found that the problem should be related to the dispersion efficiency of the mixing tank. After a period of research and discovery of some key points, I developed and produced a high-efficiency mixing bucket in my factory, and then applied it to this customer's third production line for comparison. The results were encouraging. After stirring for 5 minutes, draw back to the sub-tank. When the tank was opened for one night, the factory detected that the solid content actually reached 6.02%. It is the mixing barrel that plays a key role in stirring and dispersing the electrophoretic paint.

High-smoothness anodic electrophoretic paint