About us Products News Contact us

Tel:86-020-37400096

Phone:136 0030 4588

13124259290(Mr. Jiang)

Fax:86-020-37403361

Mailbox:ud8888@aliyun.com

Add:Liangshi Road, Liangtian, Baiyun District, Guangzhou

COPYRIGHT @ 2020 Guangzhou Youda Coating Co., Ltd. gzud.com.cn. ALL RIGHTS RESERVED. ICP:45646546-1 Powered by www.300.cn

Working voltage, destruction voltage and critical voltage of electrophoretic coating?

Page view

[Abstract]:

What is the working voltage, breakdown voltage and critical voltage of electrophoretic coating?

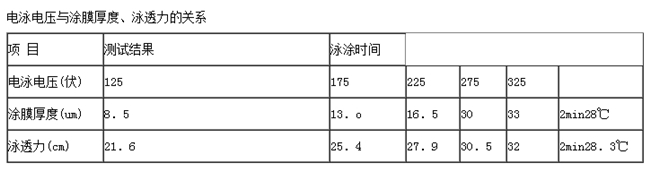

In electrophoretic coating applications, a film thickness with excellent appearance can be obtained. The voltage connected between the two electrodes is called the working voltage of electrophoretic coating (referred to as swimming coating voltage). Generally there is a certain voltage range. When the upper limit of the swim coating voltage is exceeded, the reaction on the deposition electrode intensifies, a large amount of gas is generated, the deposited coating film is cracked, the insulation is damaged, and abnormal adhesion is generated. This voltage value is called To destroy the voltage. When a certain voltage value is lower than the lower limit of the swimming coating voltage, the coating film is hardly coated (or the amount of the deposition and the redissolved coating film is offset). This voltage value is called the threshold voltage. The working voltage of electrophoresis is between the threshold voltage and the destruction voltage. Swimming coating voltage is one of the important process parameters for electrophoretic coating. In other occasions where the swimming conditions are not changed, the thickness of the swimming film and the penetrating power increase with the increase of the swimming voltage. In production practice, the thickness of the coating film is often controlled by adjusting the swimming coating voltage.

In order to obtain excellent coating film appearance and high swimming power, in the production practice, the starting voltage is generally lower to reduce the electrode response; the subsequent voltage is higher to improve the quality of swimming coating on the surface of the cavity gap, such as vertical On the elevating swimming coating equipment, the voltage is lower for the first 15.30 seconds. The working voltage of the paint is then increased, which is also called "soft start", and also to reduce the pulse current when the power is turned on. On a continuous electrophoresis line with a charged tank, the voltage is controlled in sections and divided into at least 2 sections. About 1/3 of the bus (plate) is the first section with low voltage; the latter 2/3 is higher. The second section of voltage. The coating is stopped in the electrophoresis tank for some reason. In order to prevent re-dissolution, the voltage is reduced to the critical voltage. However, this method is not good. Especially in the case of anodic electrophoresis, the anodic dissolution continues, and even the coated surface The phosphate film was completely dissolved away. · The knee factory recommends the introduction of its working voltage and destruction voltage in the technical conditions of cathodic electrophoretic coatings. For example, take a thick film electrophoretic coating as an example: under other swimming coating conditions under the best conditions, the working voltage is 150-250 volts. , The destruction voltage is 350 volts, and the thickness of the coating film obtained at each swimming voltage is introduced as follows:

150 volts—25 soil 5u, 200 volts—30 soil 5u, 250 volts. 35 soil 5u.

Destructive voltage measurement method:

This method is applicable to the determination of the breakdown voltage of electrophoretic coatings.

The main points of the measurement method:

① Increase the normal painting voltage by 40 volts for electrophoresis (low-voltage type electrophoretic paint can increase by 20 volts), and confirm that the current value decreases with the increase of the electrophoresis time. Raise another 40 volts, and repeat the operation in this way;

② When the voltage is reached: that is, as time increases, the current value does not decrease, but a rising omen appears (indicating that damage has started), the power is immediately cut off,

② Decrease the above voltage by 20 volts, and then increase or decrease by 10 volts according to the signs that the current value decreases or rises with time, until it reaches the highest voltage where the current value does not increase, which is the destruction voltage. American PPG company measurement method:

A. On cold rolled steel

When the bath temperature is 950F. Raise the voltage from 0 volts to 500 volts (within about 60 seconds). Pay attention to the voltage when the paint film smokes and the amps increase sharply. Paint a second sample at a voltage below 25 volts to ensure that the swimming board is qualified. For example; at 400 volts, there is a burning scorch, the smell and the appearance are poor, but at 375 volts, the rupture voltage is 400 volts. The electrophoresis process should not exceed the test results.

· B. On galvanized steel

The temperature of the bath solution was 95 ° C. At F, in a rising voltage (about 10 volt spacing), paint a set of samples. Change the coating time so that the thickness of the paint film of each sample is 25um. Dry the sample. Note: The voltage when the pinhole appears in the sample. ·

For example: 270V 70 seconds 25 strict m good

280V 60 seconds 25um good

290V 50 seconds 25um good

300V 40sec 25um pinhole

310V 30sec 25um pinhole

The rupture voltage is 300V.

Control the electrophoresis process not to exceed the test results